In the intricate world of textile manufacturing, achieving superior fabric quality often hinges on advanced chemical treatments. Among these, mercerization in textile stands out as a critical textile pretreatment chemical process that dramatically enhances the properties of cellulosic fibers, particularly cotton. This transformative treatment imbues cotton with increased luster, strength, and improved dye affinity. At the heart of an effective mercerization process lies a specialized mercerizing agent in textile – a penetrant designed to ensure uniform and efficient chemical action. Our High Alkali Mercerizing Penetrant for Textile Pretreatment is engineered precisely for this purpose, optimizing every step of this essential process.

Unlocking Quality: What is Mercerization in Textile?

Mercerization is a chemical finishing treatment for cellulosic materials, typically cotton yarns or fabrics, involving immersion in a concentrated solution of sodium hydroxide (NaOH) under tension. This process causes the cotton fibers to swell, altering their cross-sectional shape from kidney-bean-like to a more circular form. The result is a profound enhancement of several desirable properties:

For effective mercerization of cotton fabric, the alkali solution must penetrate the fibers rapidly and uniformly. This is where a high-quality mercerizing agent in textile becomes indispensable, ensuring the entire fabric benefits from the treatment without unevenness.

Elevating Efficiency: Our High Alkali Mercerizing Penetrant

Our High Alkali Mercerizing Penetrant for Textile Pretreatment is a professional-grade formulation specifically designed to excel in high-alkaline mercerizing processes. It is a vital component in modern textile pretreatment chemicals, ensuring optimal performance and consistency. This versatile product also demonstrates superior penetration in other applications requiring robust capabilities under high-alkaline conditions.

Key Features & Benefits:

· Exceptional Alkali Resistance: Maintains stability and efficacy even in highly concentrated caustic soda solutions.

· Outstanding Penetration: Ensures rapid and uniform wetting of cotton fibers, crucial for even mercerization of cotton fabric.

· Superior Emulsification: Effectively disperses natural waxes and impurities, preventing redeposition and promoting a cleaner fiber surface.

· Excellent Dispersing Properties: Helps in maintaining the homogeneity of the processing bath, avoiding localized concentration effects.

· Enhanced Luster and Strength: Contributes directly to the achievement of desired fabric properties.

· Improved Dyeing Uniformity: Leads to better dye absorption and levelness.

By utilizing our High Alkali Mercerizing Penetrant for Textile Pretreatment, manufacturers can achieve consistent, high-quality mercerized fabrics, optimizing subsequent dyeing and finishing processes.

Technical Edge: Product Specifications

Detailed specifications for our High Alkali Mercerizing Penetrant for Textile Pretreatment are outlined below, showcasing its robust performance characteristics.

|

Property |

Description/Value |

|

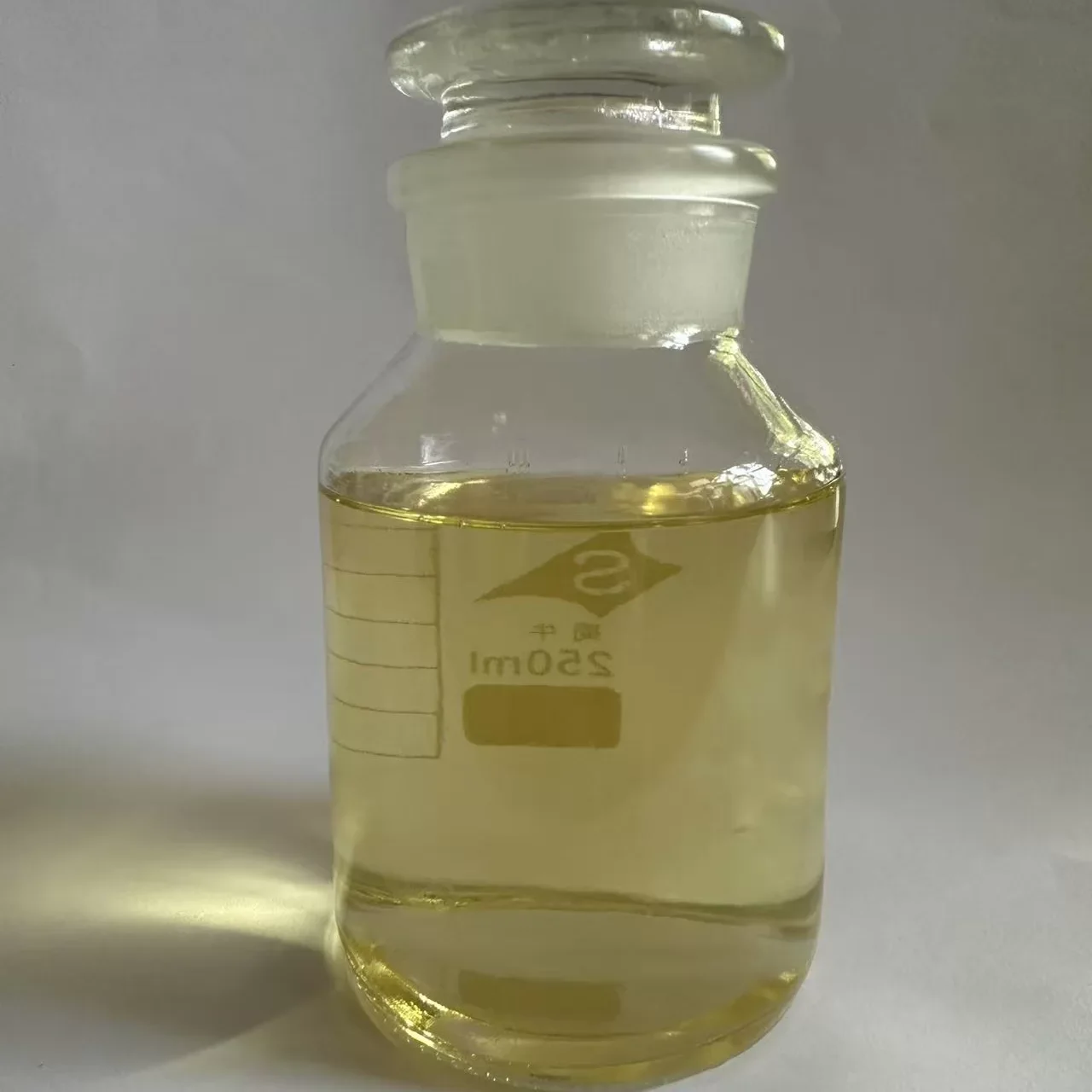

Appearance |

Colorless to pale yellow clear liquid |

|

Ionicity |

Non-ionic |

|

pH (1% solution) |

6.0 – 8.0 |

|

Solubility |

Easily soluble in water at all concentrations |

|

Alkali Resistance |

Excellent (stable up to 300 g/L NaOH at 60°C) |

|

Foaming Property |

Low to non-foaming in practical applications |

|

Wetting Time (AATCC 17-2017) |

< 5 seconds (0.1% solution in 250 g/L NaOH) |

|

Dispersing Ability |

Very good (prevents precipitation of impurities) |

|

Emulsifying Ability |

Excellent (for natural oils and waxes) |

|

Shelf Life |

12 months when stored properly in original sealed containers |

|

Packaging |

200kg plastic drums, 1000kg IBC tanks |

From Concept to Quality: The Manufacturing Journey

The production of our High Alkali Mercerizing Penetrant for Textile Pretreatment follows a rigorous, multi-stage process designed to ensure consistent quality and performance.

Manufacturing Steps:

1. Raw Material Sourcing & Inspection: We meticulously select high-purity surfactants, emulsifiers, and dispersing agents. All incoming materials undergo stringent quality checks against internal standards and industry benchmarks.

2. Precise Blending & Reaction: Materials are carefully measured and introduced into reaction vessels according to proprietary formulations. Controlled temperature and agitation ensure optimal chemical reactions and homogeneous mixing.

3. Quality Control & Testing: Throughout the production cycle, in-process samples are taken and tested for key parameters such as pH, active content, specific gravity, and initial performance indicators like wetting time and alkali stability.

4. Filtration & Purification: The product undergoes filtration to remove any potential impurities, ensuring a clean, clear final liquid.

5. Final Product Analysis: Before packaging, each batch is subjected to a comprehensive battery of tests to confirm it meets all published specifications, including advanced performance tests relevant to mercerization in textile applications.

6. Packaging & Storage: The finished product is carefully packaged into durable, chemical-resistant containers, labeled, and stored under optimal conditions to maintain its integrity and extend its service life.

Materials, Methods, and Standards:

· Key Materials: Proprietary blends of non-ionic surfactants, fatty alcohol ethoxylates, and specialty dispersing agents, all selected for their high alkali resistance and performance.

· Testing Standards: Adherence to international standards like ISO 9001 for quality management. Performance testing follows industry-recognized methods such as AATCC Test Method 17 (Wetting Agents, Evaluation of) and internal protocols for alkali stability and emulsification power.

· Service Life: When stored in original, sealed containers in a cool, dry place away from direct sunlight, the product maintains its efficacy for at least 12 months. Proper usage in the mercerization bath ensures consistent performance for the duration of the process.

· Applicable Industries: Primarily the textile industry for cotton and cellulosic blends. This includes manufacturers of apparel fabrics (denim, shirting), home textiles (towels, bed linen), industrial textiles requiring enhanced strength and absorbency, and yarn manufacturers for mercerization of cotton yarn.

Navigating the Technicalities: Key Terms and Practical Uses

Understanding the technical terminology associated with textile pretreatment chemicals like our High Alkali Mercerizing Penetrant for Textile Pretreatment is crucial for optimal application.

Technical Terminology:

· Mercerization: The process of treating cotton or other cellulosic fibers with concentrated caustic soda to improve strength, luster, and dye affinity.

· Penetrant: A chemical additive that reduces the surface tension of a liquid, allowing it to spread more easily and penetrate porous materials (like fabric) more deeply and quickly. In mercerization, it aids the caustic soda solution.

· Alkali Resistance: The ability of a chemical agent to remain stable and effective in highly alkaline (high pH) environments, such as concentrated sodium hydroxide baths.

· Emulsification: The process of forming an emulsion (a stable mixture of two immiscible liquids). In textiles, it often refers to suspending oils, fats, and waxes from the fiber surface into the processing bath.

· Dispersing Agent: A substance that helps prevent the agglomeration or clumping of particles (like impurities or precipitated substances) in a liquid, keeping them uniformly distributed.

· Caustic Soda (NaOH): Sodium hydroxide, the primary chemical used in the mercerization bath.

Usage Scenarios:

· Continuous Mercerization Ranges: Ideal for high-speed processing of woven fabrics, ensuring rapid and even wetting as fabric passes through caustic impregnation zones.

· Yarn Mercerization: Used in skein or beam mercerization processes to achieve uniform treatment of cotton yarns for knitting and weaving.

· Cold Pad-Batch Mercerization: Facilitates excellent penetration during cold pad-batch application, which can offer energy savings and process flexibility.

· Other High-Alkaline Scouring Baths: Can be effectively used in other high-alkaline pretreatment steps requiring strong wetting, emulsifying, and dispersing properties.

Beyond Penetration: Diverse Applications and Outstanding Advantages

The versatility of our High Alkali Mercerizing Penetrant for Textile Pretreatment extends across various applications within the textile industry, delivering significant advantages.

Applications:

· Cotton Fabric Mercerization: Essential for woven and knitted cotton fabrics destined for high-quality apparel, home textiles, and industrial uses.

· Cotton Yarn Mercerization: Improves the properties of cotton yarns, making them stronger, more lustrous, and easier to dye for knitting and weaving.

· Cellulosic Blend Mercerization: Can be used with blends containing cellulosic fibers (e.g., cotton-viscose) where mercerizing effects are desired on the cellulosic component.

· High-Alkaline Scouring and Washing: Effective in severe alkaline conditions for pre-cleaning and desizing operations, enhancing the removal of impurities.

Advantages:

· Superior Process Uniformity: Ensures even distribution of the caustic solution, leading to consistent mercerizing effects across the entire fabric or yarn batch.

· Enhanced Aesthetic Quality: Significantly boosts fabric luster and hand-feel, meeting high-end market demands.

· Improved Dyeing Performance: Achieves deeper, brighter, and more level dyeings, reducing the need for re-dyeing and minimizing material waste.

· Increased Production Efficiency: Faster and more effective penetration can lead to reduced processing times and higher throughput.

· Cost-Effectiveness: Optimizes chemical consumption, minimizes rejects, and enhances downstream processing, leading to overall operational savings.

· Stability and Reliability: Its advanced formulation guarantees stability and consistent performance even under the most demanding high-alkaline conditions.

Tailored Solutions: Customization for Unique Textile Needs

Recognizing that every textile mill has unique requirements, we offer comprehensive customization options for our High Alkali Mercerizing Penetrant for Textile Pretreatment. Our goal is to provide solutions that seamlessly integrate into your specific processes and enhance your product quality.

Customization Areas:

· Concentration Adjustment: While our standard formulation is highly effective, we can adjust active concentrations to match specific machinery types, fabric weights, or desired penetration speeds.

· Performance Profile Tuning: For highly specialized applications, we can fine-tune the balance of wetting, emulsifying, and dispersing properties to meet stringent performance criteria.

· Packaging Flexibility: Beyond standard drums and IBCs, we can discuss alternative packaging solutions tailored to your operational logistics and storage capabilities.

· Technical Collaboration: Our R&D team is available for in-depth consultation and collaboration to develop bespoke solutions that address specific challenges in your mercerization or other high-alkaline pretreatment processes.

· Regulatory Compliance: We can work with clients to ensure the customized product meets specific regional or international regulatory requirements for textile pretreatment chemicals.

This bespoke approach ensures that you receive a mercerizing agent in textile that not only meets but exceeds your expectations, contributing to superior fabric quality and operational efficiency.

Informed Choice: Comparing Mercerizing Penetrants

Choosing the right mercerizing agent in textile is critical for achieving optimal results and cost-efficiency. Here’s how our High Alkali Mercerizing Penetrant for Textile Pretreatment compares to other options on the market:

|

Feature |

Our Product |

Competitor A (Standard) |

Competitor B (Premium) |

|

Alkali Resistance |

Excellent (up to 300 g/L NaOH) |

Good (up to 200 g/L NaOH) |

Very Good (up to 250 g/L NaOH) |

|

Penetration Speed (Wetting Time) |

Rapid (< 5 seconds) |

Moderate (7-10 seconds) |

Fast (5-7 seconds) |

|

Emulsification Power |

Superior |

Good |

Very Good |

|

Dispersing Ability |

Excellent |

Average |

Good |

|

Foaming Tendency |

Low to Non-foaming |

Moderate |

Low |

|

Cost-Effectiveness |

High (optimal dosage, superior results) |

Medium (may require higher dosage or re-processing) |

Medium-High (higher initial cost) |

|

Technical Support |

Comprehensive & Responsive |

Basic |

Good |

Trusted Performance: Certifications, Data, and Compliance

Our commitment to quality and safety is underlined by rigorous testing, adherence to authoritative standards, and relevant certifications for our High Alkali Mercerizing Penetrant for Textile Pretreatment.

Certifications:

· ISO 9001 Certified: Our manufacturing facilities and quality management systems comply with international standards for consistent product quality.

· REACH Compliant: All raw materials and the final product are registered and compliant with European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations.

· OEKO-TEX Standard 100 Guidelines (Product Class IV): While the chemical itself is not certified, its components and formulation are designed to be safe for use in textiles that meet OEKO-TEX Standard 100 requirements for human-ecological safety.

Test Data:

· Wetting Time Test: Internal lab tests consistently show a wetting time of less than 5 seconds (using AATCC Test Method 17-2017) in a 250 g/L NaOH solution at 25°C, demonstrating superior penetration speed.

· Alkali Stability Test: The penetrant remains clear and stable without any signs of separation or precipitation after 24 hours in a 300 g/L NaOH solution at 60°C.

· Emulsification Test: Demonstrates over 90% emulsification of typical cotton waxes in a simulated mercerizing bath, significantly contributing to fabric cleanliness.

Authoritative Standards:

· AATCC Test Methods: Our internal quality control and performance evaluations are guided by relevant American Association of Textile Chemists and Colorists (AATCC) standards for wetting, absorbency, and chemical stability.

· ASTM Standards: Physical and chemical properties are tested in accordance with applicable American Society for Testing and Materials (ASTM) standards.

Seamless Partnership: Logistics, Assurance, and Support

We are committed to providing not only a superior mercerizing agent in textile but also a comprehensive service package that ensures a smooth and reliable partnership.

Delivery Time:

· Standard Lead Time: Typically 7-14 business days from order confirmation, depending on order size and destination.

· Expedited Options: Available upon request for urgent requirements. Please contact our sales team to discuss express shipping solutions.

· Global Logistics: We leverage a robust network of logistics partners to ensure timely and secure delivery worldwide.

Warranty:

· We offer a product quality warranty against manufacturing defects and guarantee that our High Alkali Mercerizing Penetrant for Textile Pretreatment meets all published specifications when stored and used according to our recommendations.

· For full details on our warranty terms and conditions, please refer to our standard sales agreement or contact our customer service.

After-Sales Support:

· Dedicated Technical Assistance: Our team of textile chemists and technical specialists is available to provide expert guidance on product application, process optimization, and troubleshooting related to mercerization in textile.

· Application Training: We can offer training sessions for your production team to ensure they maximize the benefits of our product and understand best practices for textile pretreatment chemicals.

Continuous Improvement: We value customer feedback and continuously strive to enhance our products and services to meet evolving industry needs.

Proven Success: Case Studies & Valued Customer Insights

The effectiveness of our High Alkali Mercerizing Penetrant for Textile Pretreatment is best demonstrated through real-world applications and the feedback from our satisfied clients.

Real-World Case Study:

Case Study: Enhanced Dyeing Uniformity for a Denim Manufacturer

A leading denim manufacturer faced challenges with inconsistent dye uptake and streakiness after mercerization of cotton fabric. They were using a competitor's standard mercerizing agent in textile. Upon switching to our High Alkali Mercerizing Penetrant for Textile Pretreatment, they observed a dramatic improvement. The superior penetration and emulsification properties of our product ensured uniform caustic treatment, leading to a perfectly level surface for dyeing.

Results: Reduced dyeing defects by 15%, achieved 10% deeper shades with the same dye recipe, and improved overall fabric luster by an average of 20% (measured spectrophotometrically). This led to significant cost savings in terms of reduced re-dyeing and increased first-pass quality.

Customer Feedback:

"We've been using their High Alkali Mercerizing Penetrant for over a year now, and the consistency in our mercerized cotton is remarkable. The dye uptake is noticeably better, and we've significantly cut down on reprocessing."

— Production Manager, Leading Knit Fabric Mill

"The technical support team is incredibly knowledgeable. They helped us optimize the dosage for our specific setup, leading to better results and chemical efficiency. This mercerizing agent in textile is truly high-performance."

— R&D Head, Premium Shirting Manufacturer

Your Questions Answered: Comprehensive FAQ

Q: What is the recommended dosage for the High Alkali Mercerizing Penetrant for Textile Pretreatment?

A: The optimal dosage typically ranges from 2-5 g/L depending on the concentration of caustic soda, the type of fabric, and the specific machinery. We recommend conducting preliminary trials or consulting our technical team for precise recommendations for your application.

Q: Is this mercerizing agent in textile compatible with other textile pretreatment chemicals?

A: Yes, it is generally compatible with most common pretreatment chemicals, including hydrogen peroxide, chelating agents, and stabilizers used in high-alkaline baths. However, it's always advisable to perform compatibility tests with your specific formulations before full-scale application.

Q: What safety precautions should be observed when handling this product?

A: Like all industrial chemicals, appropriate personal protective equipment (PPE) such as safety goggles, chemical-resistant gloves, and protective clothing should be worn. Ensure adequate ventilation. Refer to the Material Safety Data Sheet (MSDS) for complete safety information and handling guidelines.

Q: Can this product be used for synthetic fibers or blends?

A: Our penetrant is primarily formulated for cellulosic fibers (e.g., cotton) undergoing mercerization. While it is stable in high alkali conditions, the mercerization process itself does not significantly affect synthetic fibers. It may be used in blends to treat the cellulosic component, but its core function is optimized for cotton.

Q: How does this penetrant contribute to environmental sustainability?

A: By ensuring a more efficient and uniform mercerization process, our product helps reduce chemical waste from re-processing and re-dyeing. Its high efficacy at lower concentrations also contributes to minimizing overall chemical usage, aligning with sustainable textile production practices.

References

1. Textile Science and Technology. Mercerization. ScienceDirect. (General information on mercerization process and effects).

2. AATCC Test Method 17: Wetting Agents, Evaluation of. (Standard method for evaluating wetting agents in textile applications).

3. Gulrajani, M. L., & Gupta, S. (2009). Mercerization of Cotton. Textile Progress, 41(3), 177-226. (In-depth review of mercerization technology).

4. OEKO-TEX Standard 100. (Information on human-ecological safety standards for textile products).

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals