A practical insider’s guide to Fabric Mercerization in 2025

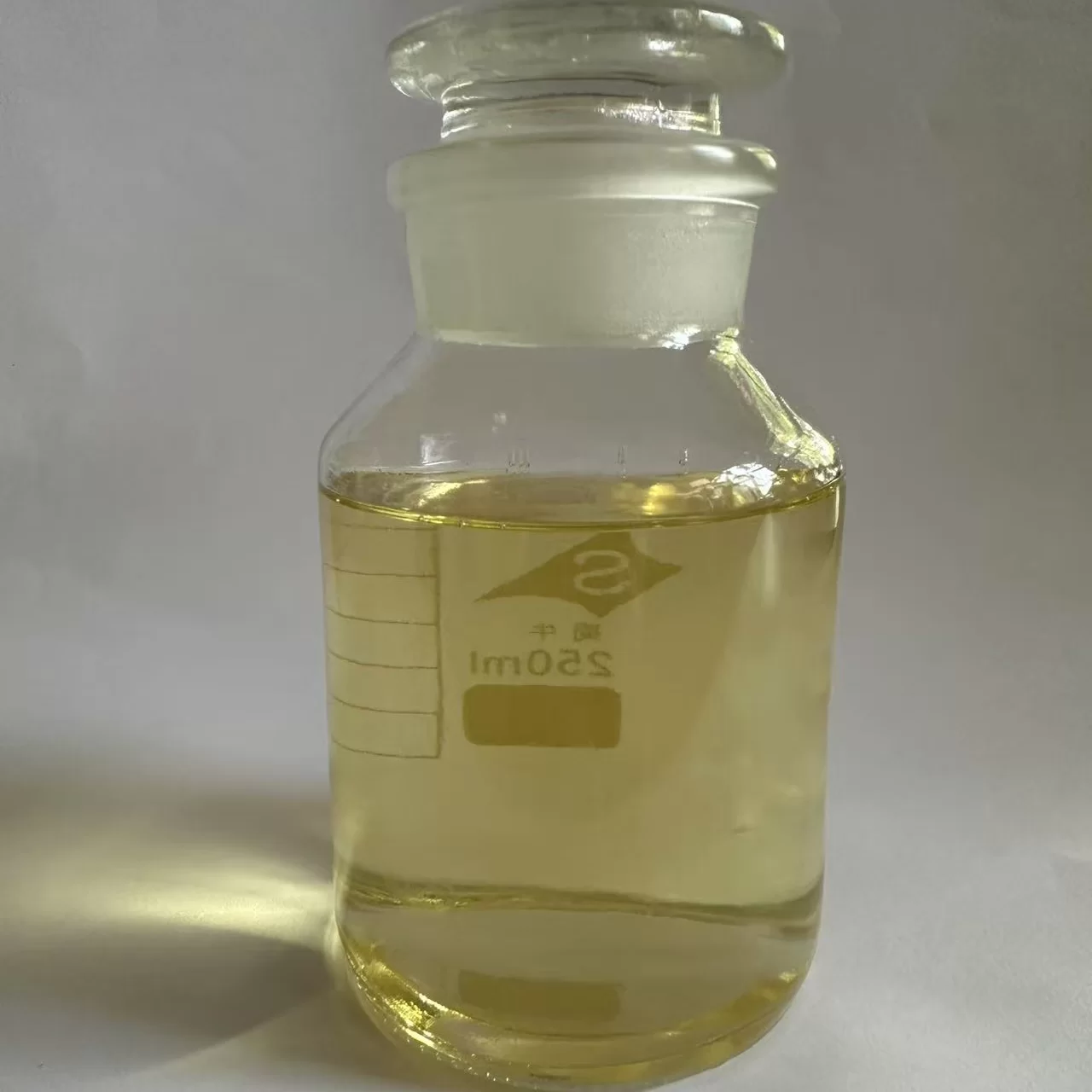

If you’ve ever handled a cotton poplin that looked almost silkier than it had any right to, you’ve met mercerization’s handiwork. In mills I visit, teams still debate recipe tweaks, but one quiet constant is the penetrant. The High Alkali Mercerizing Penetrant for Textile Pretreatment—formulated in Han Village, Zhao County, Shijiazhuang, Hebei—has been popping up on more lines lately. To be honest, that tracks with what the numbers say about modern, caustic-heavy lines chasing lower energy and higher pick-up consistency.

Why does Fabric Mercerization matter? Because uniform wetting under high caustic determines luster, dye uptake, and tensile changes—basically the whole show.

Process flow and real-world parameters

- Materials: 100% cotton or high-cotton blends; ring-spun yarns, open-width fabrics, terry, denim.

- Alkali bath: NaOH ≈ 18–30% w/w; temperature 18–25°C to stabilize fiber swelling.

- Penetrant dosage: 1.0–3.0 g/L in the caustic; some mills push to 4.0 g/L for dense twills.

- Method: Rapid wetting, controlled dwell 20–60 s under tension; then thorough washing and neutralization (e.g., acetic acid pH 6.5–7).

- Targets: Wet pick-up 90–110% (fabric-dependent); minimal foam; even penetration across selvedge-to-center.

Testing standards that keep everyone honest: AATCC 79 for wetting time; ISO 105-C06 for colorfastness after; ASTM D5035 tensile; ISO 6330 for home-laundering durability. Many customers say they’ll accept an extra second or two of wetting if foam stays tame—fair point.

Product specs (core data, ≈ values)

| Product Name | High Alkali Mercerizing Penetrant for Textile Pretreatment |

| Origin | Han Village, Zhao County, Shijiazhuang City, Hebei, China |

| Chemistry | Nonionic/anionic surfactant blend, high-alkali resistant |

| pH (1% aq.) | ≈ 6.0–8.0 |

| Alkali resistance | Stable up to ≈ 320 g/L NaOH |

| Dosage (guide) | 1.0–3.0 g/L in mercerizing bath; real-world use may vary |

| Foam profile | Low to moderate; compatible with defoamers |

| Compliance | Designed to meet ZDHC MRSL v3.1; supports OEKO-TEX inquiries |

| Shelf life | ≈ 12 months sealed; store cool and dry |

Where it shines

Open-width Fabric Mercerization for poplin and sateen, yarn mercerization for combed yarns, and—surprisingly—loop-heavy terry where penetration is famously tricky. Benefits: faster wetting, more even NaOH uptake, cleaner luster, and steadier shade depth after dyeing.

Vendor comparison (field notes)

| Option | Alkali resistance | Wetting time (AATCC 79, cotton, 25°C) | Foam | Notes |

|---|---|---|---|---|

| High Alkali Mercerizing Penetrant | High (≈ 320 g/L) | 6–10 s | Low–med | Balanced wetting/defoming; good on dense twills |

| Generic wetting agent | Medium | 10–18 s | Medium | Cost-lean, but drops off in strong caustic |

| Imported premium brand | High | 5–9 s | Low | Excellent, higher landed cost/lead-time |

Mini case study: denim mill

A South Asia denim plant switched on the penetrant for rope-dyed warp mercerization. Results after two weeks (internal QC, n=3 lots): wet pick-up +6% (from 86±3% to 92±2%), K/S at 620 nm +5–7% on reactive shades, and 12% fewer streak claims. Operators noted “easier” foam control—subjective, but echoed by three shifts.

Customization, testing, and compliance

- Recipe tuning: defoamer pairing, temperature tweaks, pad pressure mapping.

- Lab support: AATCC 79 wetting, ISO 105-C06 washfastness, ASTM D5035 tensile retention post-Fabric Mercerization.

- Documentation: ZDHC MRSL conformity, safety data, and OEKO-TEX-relevant support.

Industry trend check: mills are pushing cooler baths and tighter tension control to save energy yet preserve fiber swelling. Penetrants that stay active in hard caustic—without foaming out—are the quiet heroes. It seems that’s where this product finds its groove.

Citations

- AATCC 79: Testing the Water Resistance of Textiles—Wetting.

- ISO 105-C06: Textiles—Tests for colour fastness—Part C06.

- ZDHC MRSL v3.1—Manufacturing Restricted Substances List.

- OEKO-TEX ECO PASSPORT/STANDARD 100—Chemical and product safety frameworks.

- ASTM D5035: Standard Test Method for Breaking Force and Elongation of Textile Fabrics.

- ISO 6330: Domestic washing and drying procedures for textile testing.

- Textile finishing literature on Fabric Mercerization fundamentals and NaOH swelling behavior.

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals