fabric mercerization is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Textile additive manufacturing.

This article explores how TAIAN GROUP LIMITED supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- fabric mercerization Overview

- Benefits & Use Cases of fabric mercerization in Textile additive manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on fabric mercerization from TAIAN GROUP LIMITED

fabric mercerization Overview

Fabric mercerization—especially the mercerization of cotton fabric—is a controlled treatment in which cellulosic fibers are exposed to high-alkali sodium hydroxide (typically 25–30% NaOH) under tension. This classic pretreatment process in textile manufacturing swells the fiber, straightens fibrils, and increases perimeter and roundness, which enhances dye affinity, tensile strength, dimensional stability, and luster. In modern lines, achieving uniform penetration of alkali through dense yarns and compact constructions is critical; this is where specialized auxiliaries, such as high-alkali penetrants, add measurable value. As a cornerstone of mercerization in textile processing, the right chemistry ensures rapid, even wetting, controlled caustic diffusion, and clean rinse-off, enabling consistent color reproducibility and premium handle.

- Relevance: In woven and knit cotton (and cotton-rich blends), mercerization improves dye uptake for reactive and vat systems, reduces skew, and yields brighter, deeper shades with improved fastness.

- Technical note: Effective mercerization balances alkali concentration, temperature, dwell time, and fabric tension, supported by low-foaming, high-alkali-stable surfactants that ensure uniform NaOH penetration and rapid neutralization/wash-off.

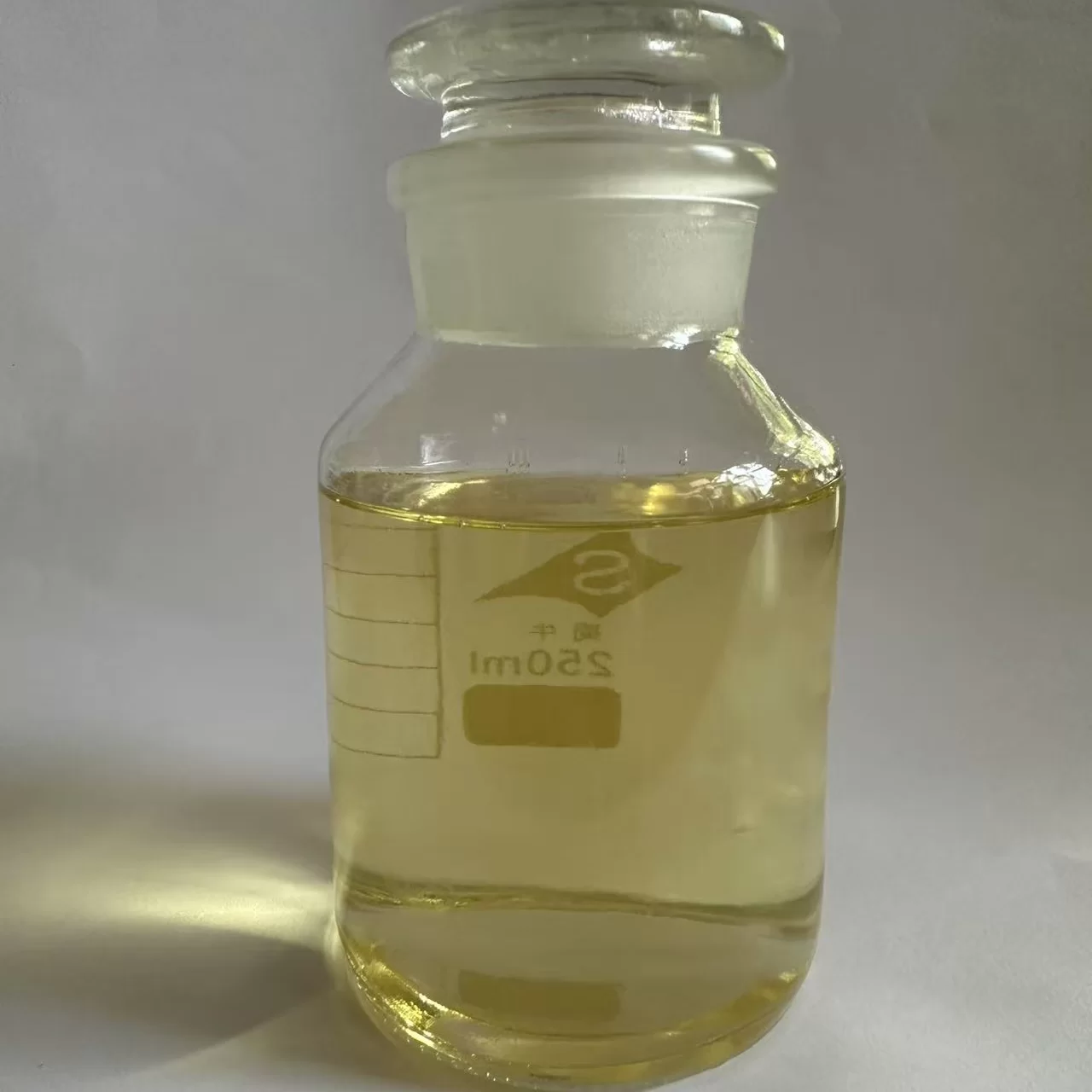

- Manufacturer: TAIAN GROUP LIMITED supplies a High-Alkali Mercerizing Penetrant engineered for severe caustic environments, helping mills stabilize quality across broad GSM ranges and constructions.

Benefits & Use Cases of fabric mercerization in Textile additive manufacturing

In Textile additive manufacturing and continuous preparation lines, fabric mercerization acts as a precision pre-stage that boosts downstream coloration yields and process stability. Whether for premium shirting, knit tees, denim, or home textiles, mills leverage mercerization to achieve a brighter surface, higher dye fixation, and reduced shade variability. TAIAN GROUP LIMITED’s high-alkali mercerizing penetrant accelerates wetting in compact yarns and high-density weaves, ensuring the caustic reaches the fiber core quickly and uniformly. The result is consistent swelling and controlled luster without over-exposure or surface streaking—key for high-speed ranges and sensitive fashion programs.

- Applications: Continuous mercerization for poplin, sateen, and oxford; pad–batch or chain mercerization for denim; preparation of cotton-rich blends prior to reactive dyeing or digital printing workflows.

- Competitive advantages: High alkali stability, fast and deep penetration, low foaming under turbulence, effective rinsability, and compatibility with standard NaOH concentrations used in mercerization in textile lines.

- TAIAN expertise: Backed by application labs and mill-scale insights, TAIAN GROUP LIMITED helps B2B decision makers tune liquor ratios, pick-up, and dwell time to raise first-pass quality and reduce rework.

Cost, Maintenance & User Experience

Total cost of ownership in mercerization spans chemicals, utilities, line speed, rework, and water treatment. By promoting rapid wetting and uniform alkali diffusion, a robust mercerizing penetrant contributes to shorter dwell times, fewer shade corrections, and more stable pick-up—factors that improve throughput and reduce off-quality meters. Mills report smoother rinsing and neutralization when the surfactant system is readily removable, which can translate into lower water demand and faster line changeovers. Equipment maintenance also benefits from low-foam profiles that reduce foam-related stops and improve levelness at high speeds.

- TCO & ROI: Optimized alkali penetration, fewer defects, and stable shade build can improve right-first-time rates—key drivers of ROI in mercerization of cotton fabric.

- User feedback: Process engineers in the Chemical raw material and chemical product manufacturing industry value auxiliaries that stay effective in strong NaOH while rinsing off cleanly, minimizing residual surfactant that could affect dyeing.

Sustainability & Market Trends in manufacturing

Sustainability in textile preparation focuses on water, energy, chemical stewardship, and compliance. In the pretreatment process in textile operations, auxiliaries that enable efficient alkali use, faster wash-off, and lower rework help reduce overall footprint. Brands increasingly expect mills to adopt formulations that are APEO/NPEO-free and designed to support conformance with leading restricted-substance expectations. At the same time, market growth in premium cotton categories—including elevated basics, refined shirtings, and denim—keeps mercerization strategically important for visual quality and dye yield, particularly as digital reactive printing expands.

- Regulatory and brand drivers: Preference for cleaner chemistries, efficient rinse profiles, and auxiliaries that align with contemporary sustainability frameworks.

- TAIAN GROUP LIMITED’s positioning: A forward-thinking supplier investing in high-alkali-stable, low-foam penetrants to help mills reduce waste and improve resource efficiency during mercerization.

Conclusion on fabric mercerization from TAIAN GROUP LIMITED

Fabric mercerization remains a pivotal step for mills seeking superior luster, dye depth, and dimensional stability in cotton-rich programs. By pairing optimized process control with a high-alkali mercerizing penetrant, manufacturers can raise first-pass quality, streamline rinsing, and reinforce sustainability goals. TAIAN GROUP LIMITED stands out as a reliable partner delivering chemistry tailored to modern mercerization lines and the demands of Textile additive manufacturing.

- Value recap: Better wetting, uniform alkali diffusion, low foam, and clean rinse-off support consistent, high-quality mercerization in textile.

- Reputation: TAIAN GROUP LIMITED combines application expertise with dependable supply for B2B operations.

- Strong CTA: Contact us: email: sales@taianchem.hk — Visit our website: https://www.dyeingchem.com — Explore the product: High-Alkali Mercerizing Penetrant

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals