fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Textile additive manufacturing. This article explores how TAIAN GROUP LIMITED supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile Overview

- Benefits & Use Cases of fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile in Textile additive manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile from TAIAN GROUP LIMITED

fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile Overview

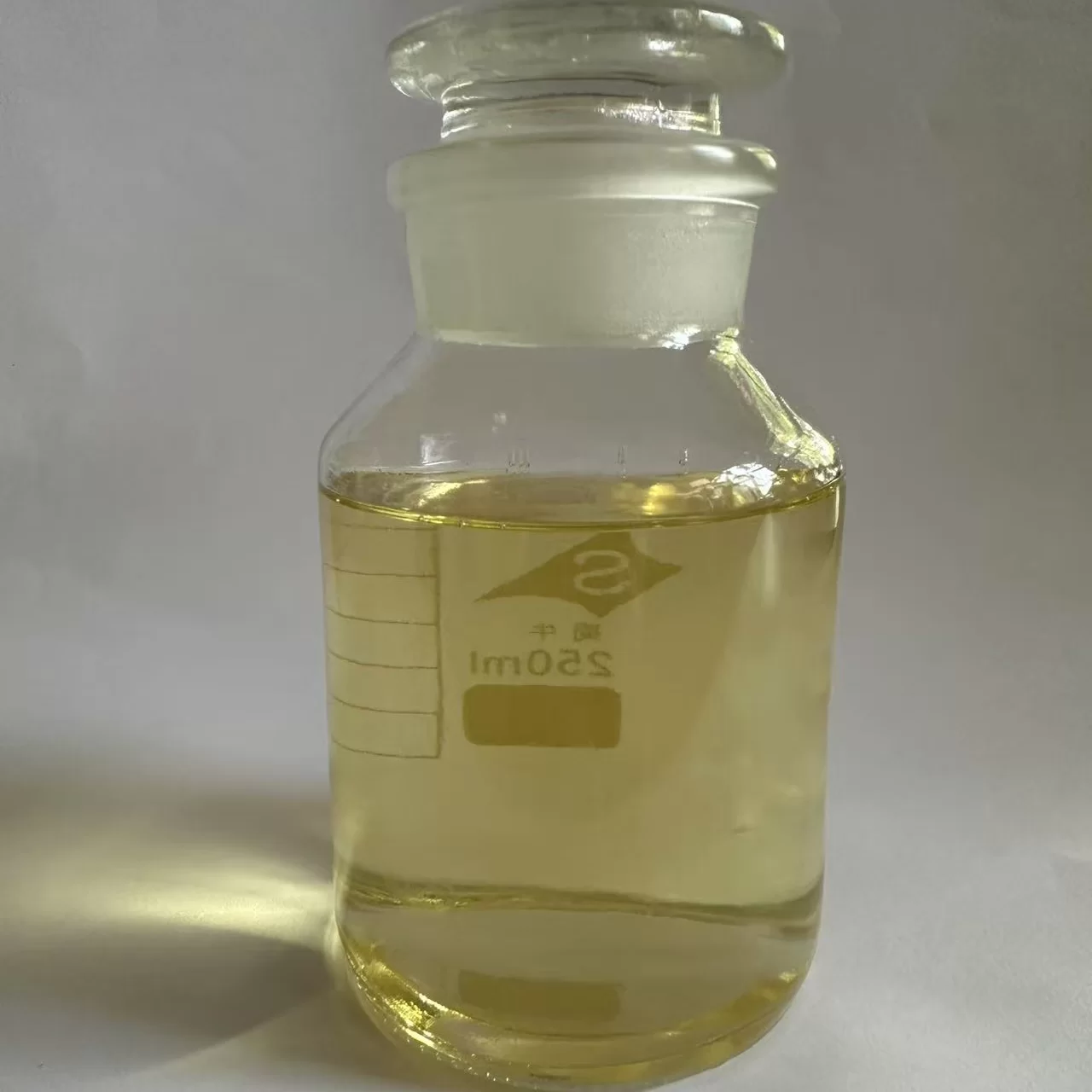

Fabric mercerization is a critical pretreatment process in textile manufacturing, especially for cotton and cotton-rich blends. During the mercerization of cotton fabric, fibers are treated under high-alkali conditions (typically concentrated sodium hydroxide under controlled tension) to improve dye uptake, luster, dimensional stability, and strength. A high-alkali mercerizing penetrant is the workhorse additive that ensures fast and uniform wetting of the cotton structure in concentrated caustic, enabling consistent results at industrial speeds.

TAIAN GROUP LIMITED formulates a high-alkali-stable penetrant engineered for mercerization in textile lines, supporting both open-width fabric mercerizers and yarn mercerization systems. The product is designed for rapid penetration in 18–30% NaOH ranges, low foam under strong agitation, and compatibility with caustic recovery systems. Typical use levels can be optimized (e.g., 1.0–3.0 g/L) based on fabric weight, construction, and line speed. In trials with woven cotton and cotton/modal blends, mills reported more even caustic pick-up, improved shade reproducibility after dyeing, and cleaner rinsing, all of which translate to greater process control and lower rework.

With decades of specialty chemical know-how, TAIAN GROUP LIMITED is a reliable manufacturer and partner for processors seeking robust, high-performance solutions for mercerization and the broader pretreatment process in textile value chains.

Benefits & Use Cases of fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile in Textile additive manufacturing

In Textile additive manufacturing and continuous preparation lines, mercerization is leveraged to upgrade cotton substrates for premium coloration and hand feel. Key applications include open-width mercerization of shirting and bottom-weight fabrics, knitted cotton for elevated luster and recovery, yarn mercerization for high-uniformity cone packages, and mercerization prior to reactive or vat dyeing to boost color yield.

TAIAN GROUP LIMITED’s high-alkali penetrant supports these applications by delivering:

- Fast, even wetting under high caustic, ensuring uniform caustic penetration through dense or compact constructions.

- Low-foam performance at high turbulence, protecting line stability and preventing defects like spots and streaks.

- Broad compatibility with additives and rinsing steps, aiding clean removal during neutralization and after-wash.

- Consistent results across a wide temperature window typical of mercerization, supporting higher line speeds and stable tension control.

Compared with commodity surfactants, a purpose-built penetrant for mercerization in textile processing yields superior dye affinity, improved brightness/whiteness in whites, and better dimensional stabilization. TAIAN GROUP LIMITED provides technical support for process audits, dosing optimization, and integration with existing caustic recovery equipment—helping mills convert formulation advantages into measurable production KPIs.

Cost, Maintenance & User Experience

Total cost of ownership for a mercerization program is driven by chemical efficiency, line productivity, and downstream savings. By enabling rapid, uniform wetting, the right penetrant reduces re-dye rates, shade corrections, and stoppages—lowering overall dye and energy use after mercerization of cotton fabric. Many mills also observe improved caustic pick-up control, which supports higher first-pass yield and stable hand feel across lots.

From a maintenance perspective, TAIAN GROUP LIMITED’s penetrant is designed for clean rinsing and compatibility with standard filtration and dosing systems. Routine best practices—such as keeping dosing pumps calibrated, checking foam guard equipment, and monitoring alkali concentration and fabric tension—sustain performance and ROI. Typical storage and handling guidelines (sealed containers, ambient storage, and standard PPE when handling caustic and auxiliaries) further protect product integrity and operator safety.

Customer feedback from Chemical raw material and chemical product manufacturing industry users highlights stable foam profiles, reliable performance over varying NaOH concentrations, and consistent results across different cotton constructions. The outcome is a lower total processing cost and improved quality metrics that matter to B2B decision makers: uniformity, predictability, and throughput.

Sustainability & Market Trends in manufacturing

Sustainability expectations for fabric mercerization are accelerating. Brands and mills are prioritizing reduced caustic and water consumption, higher recovery rates, and safer chemistries that align with regional regulations and voluntary standards. Closed-loop caustic recovery systems, optimized wetting and penetration, and precise tension control all help minimize resource use during the pretreatment process in textile operations.

TAIAN GROUP LIMITED aligns with these trends by advancing high-alkali-stable penetrants that work efficiently with caustic recovery, support lower rework, and reduce downstream chemical load through better dye fixation. The company’s product stewardship framework emphasizes compliance with prevailing regulatory regimes and evolving brand MRSL expectations, while technical service teams help customers benchmark consumption and improve KPIs like water, energy, and effluent quality.

Market momentum favors mills that can pair mercerization excellence with data-driven process control and sustainability reporting. As regulatory and buyer requirements evolve, solutions that enhance mercerization in textile workflows while enabling measurable environmental gains will remain a strategic differentiator.

Conclusion on fabric mercerization,mercerization of cotton fabric,mercerization in textile,mercerization,pretreatment process in textile from TAIAN GROUP LIMITED

For mills seeking premium quality and reliable throughput, fabric mercerization powered by a dedicated high-alkali penetrant is a proven lever. The mercerization of cotton fabric enhances dye uptake, luster, and stability, and the right additive makes the pretreatment process in textile both predictable and efficient. TAIAN GROUP LIMITED combines robust chemistry with technical service to help manufacturers achieve consistent, scalable results.

Contact us: email: sales@taianchem.hk

Visit our website: https://www.dyeingchem.com

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals