Sulphur Dyes is a key solution in the chemical industry industry, specifically within Dye manufacturing and Textile dye manufacturing.

This article explores how TAIAN GROUP LIMITED supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Sulphur Dyes Overview

- Benefits & Use Cases of Sulphur Dyes in Textile dye manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on Sulphur Dyes from TAIAN GROUP LIMITED

Sulphur Dyes Overview

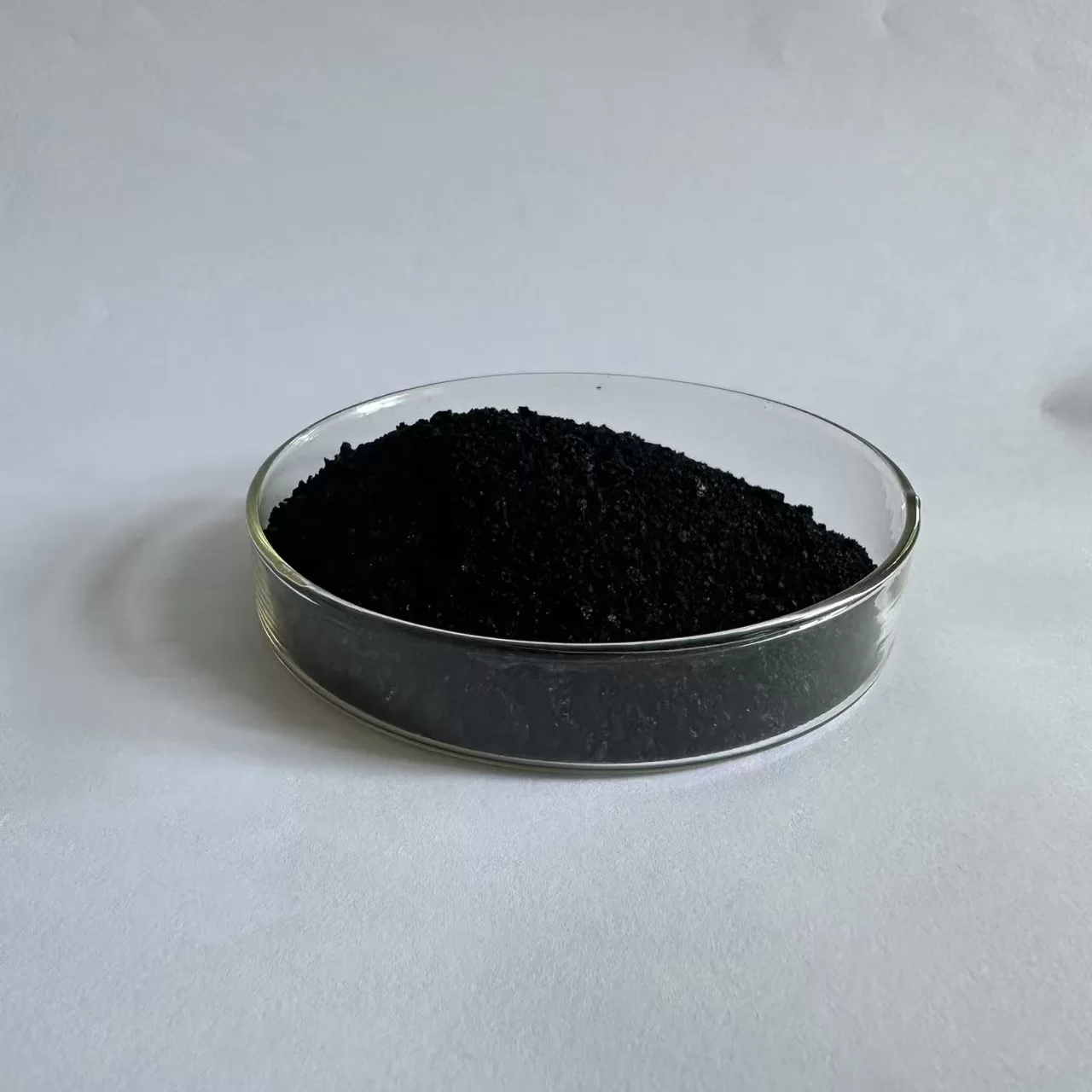

Sulphur Dyes are a class of substantive dyes prized by textile dye manufacturing for their robust fastness, cost efficiency, and deep, earthy shade range—especially the iconic sulphur black for cotton and other cellulosic fibers. In the dyehouse, these dyes are applied in their reduced (leuco) form under alkaline, reducing conditions for high uptake, then re-oxidized to deliver durable, wash- and light-fast shades. Typical application temperatures reach 80–95°C with controlled pH and oxidation, enabling consistent bulk production with excellent reproducibility.

Understanding the properties of sulphur dyes helps B2B decision makers balance performance with process economics: high substantivity to cellulose, good build-up, strong levelness in jet/winch/pad dyeing, and compatibility with denim, workwear, and piece-dyed cotton programs. TAIAN GROUP LIMITED specializes in sulphur dyes manufacturing, offering solid sulphur black grades engineered for high strength, low dusting, and cleaner reduction. Their production controls focus on batch-to-batch consistency, filtration precision, and controlled particle distribution—key to minimizing specks and maximizing levelness on large lots. A typical case study from denim finishing shows reduced re-dye rates and improved shade repeatability when switching to TAIAN’s solid sulphur black, cutting rework and stabilizing lead times in seasonal ramps.

Benefits & Use Cases of Sulphur Dyes in Textile dye manufacturing

In textile dye manufacturing, the uses of sulphur dyes center on mass-market cotton programs: denim (warps and garments), heavy knits, towels, and industrial workwear. Sulphur black remains the benchmark for deep, neutral blacks and rich charcoals with good rubbing and wash fastness after proper oxidation and soaping. Beyond black, tinted shades (olive, brown, navy) enable cost-effective, muted palettes popular in utility apparel and garment dyeing. The chemistry suits both exhaust and pad-steam routes, integrates with cationic after-fixers for enhanced wet fastness, and adapts to garment-dye cycles for vintage looks.

- Competitive advantages: high shade depth at low cost per kg of fabric, strong build-up, and robust fastness post-oxidation.

- Operational versatility: suitable for jet/winch/pad lines, with stable handling in solid and liquid forms.

- Quality assurance: controlled particle size and filtration minimize specking and barre on fine knits.

TAIAN GROUP LIMITED brings deep process know-how to scale-up trials, lab-to-bulk shade matching, and bath optimization. As one of the experienced sulphur dyes manufacturers, the company’s technical team supports mills in fine-tuning reduction/oxidation balance, salt/alkali windows, and soaping sequences—reducing off-shade risk and cycle time while lifting right-first-time percentages.

Cost, Maintenance & User Experience

From a total cost of ownership perspective, sulphur dyes deliver a strong ROI compared to alternatives like vat or high-depth reactive routes. Key levers include lower dyestuff cost per shade depth, high exhaustion leading to reduced reworks, and straightforward equipment requirements. For denim and workwear programs, sulphur black can cut cost-per-garment without sacrificing the fastness profile buyers expect, particularly when combined with optimized oxidation and soaping that stabilize crocking performance.

Mills working with TAIAN GROUP LIMITED report smoother bulk adoption due to tight lot-to-lot consistency and predictable levelling behavior. User feedback often highlights:

- Reduced shade drift across long runs, supporting stringent buyer color standards.

- Lower re-dye rates and improved machine uptime due to cleaner running and less specking.

- Responsive technical support, from lab dips to bulk SOPs, accelerating qualification cycles.

Routine maintenance focuses on consistent reduction conditions, controlled oxidation (air, peroxide, or nitrite systems), and proper after-soaping to lock in fastness. With these best practices, buyers realize stable quality and predictable costing—critical inputs for B2B decision makers managing capacity planning and margin targets.

Sustainability & Market Trends in chemical industry

Sustainability remains central to the chemical industry, with brands and mills seeking lower-impact recipes, reduced sulfide load, and better effluent profiles. Modern developments in sulphur dyes include low-sulfide or sulfide-controlled systems, improved bath exhaustion, and auxiliaries that enhance fixation and rinsability—cutting water, energy, and chemical demand per kilogram of fabric. Meanwhile, traceability, safer chemistry lists, and wastewater benchmarks are increasingly embedded in sourcing criteria, shaping supplier selection and long-term partnerships.

TAIAN GROUP LIMITED positions itself as a forward-thinking partner by prioritizing cleaner formulations, application guidance that reduces chemical overuse, and documentation to support compliance reviews. For mills scaling denim, workwear, and garment-dye programs, this means practical pathways to lower COD/BOD impact, disciplined oxidation/soaping steps, and chemistry selection aligned with buyer requirements. Market momentum for timeless blacks and utility palettes continues to favor sulphur dye platforms, where performance, cost control, and responsible processing intersect.

Conclusion on Sulphur Dyes from TAIAN GROUP LIMITED

Sulphur Dyes remain a cornerstone for textile dye manufacturing, combining high shade depth, reliable fastness, and compelling economics—especially with sulphur black programs for denim and workwear. With proven process stability and well-understood properties of sulphur dyes, mills can scale confidently and meet demanding buyer specs. TAIAN GROUP LIMITED reinforces this value with consistent quality, technical expertise, and a sustainability-minded approach to formulation and application.

- Contact us: email: sales@taianchem.hk

- Visit our website: https://www.dyeingchem.com

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals