Fabric Mercerization is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Textile additive manufacturing.

This article explores how TAIAN GROUP LIMITED supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Fabric Mercerization Overview

- Benefits & Use Cases of Fabric Mercerization in Textile additive manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Fabric Mercerization from TAIAN GROUP LIMITED

Fabric Mercerization Overview

Fabric mercerization—often described as the mercerization of cotton fabric—is a controlled treatment in strong alkali that transforms cotton’s fiber morphology to deliver higher luster, improved dye uptake, superior dimensional stability, and better tensile strength. Within the pretreatment process in textile, mercerization in textile is the step that sets premium cotton goods apart, enabling deeper, brighter shades and a smoother, more uniform hand. Achieving this consistently requires a high-alkali-stable penetrant that drives rapid, even caustic impregnation with low foam and excellent rinsability.

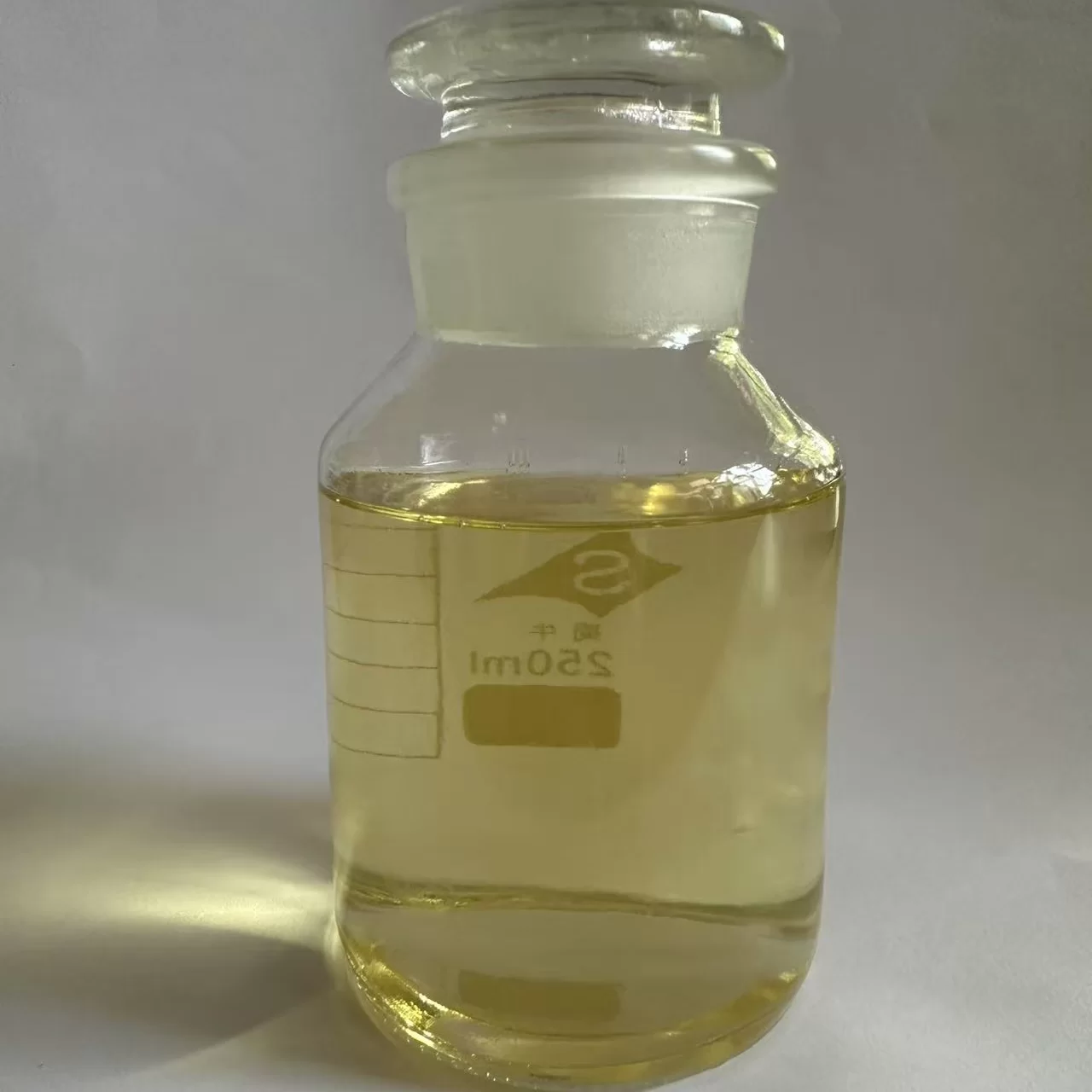

TAIAN GROUP LIMITED formulates a high-alkali mercerizing penetrant engineered for demanding continuous and pad-chain lines. It is designed to maintain performance under concentrated caustic conditions, support fast wetting on dense weaves and compact knits, and remain compatible with common sequestrants and stabilizers. In a recent denim finishing trial, a mill adopted TAIAN’s penetrant to address streaks and shade barré; the switch resulted in noticeably more uniform pick-up through the fabric width and more repeatable shade build after dyeing—key drivers of first-quality yield. As a reliable manufacturer in the Chemical raw material and chemical product manufacturing industry, TAIAN GROUP LIMITED backs its auxiliaries with process guidance to help plants stabilize mercerization windows and reduce variability.

Benefits & Use Cases of Fabric Mercerization in Textile additive manufacturing

In textile additive manufacturing and advanced finishing, mercerization of cotton fabric enhances the performance of reactive dyeing, garment-dyed programs, and high-definition printing. Typical applications include fine shirting, premium towels, mercerized ringspun knits, and yarn or piece mercerization for fashion and home textiles. By enabling rapid, uniform wetting in caustic, TAIAN’s penetrant helps achieve even alkali diffusion, minimizing streaks and mitigating risk of pinholes or surface defects on compact constructions and blended cotton-rich fabrics.

- Deeper, cleaner shades: higher dye affinity and build in reactive systems reduce re-dyes and shade correction cycles.

- Low-foam profile: stable operation at high line speeds and in high-turbulence boxes, reducing overflow and fabric defects.

- Process robustness: consistent performance across water hardness and temperature swings supports reliable pretreatment process in textile lines.

- Operational compatibility: works with standard caustic recovery and rinse sequences to streamline downstream neutralization and washing.

With deep expertise in mercerization in textile chemistry and continuous finishing, TAIAN GROUP LIMITED supports mills with dosing guidance, pick-up control strategies, and start-up playbooks to help teams lock in shade reproducibility and maximize first-pass yield.

Cost, Maintenance & User Experience

Total cost of ownership in fabric mercerization is driven by throughput, first-quality yield, caustic consumption, energy and water use, and maintenance hours. A high-performance mercerizing penetrant can reduce cost per meter by enabling faster wetting (shorter dwell), lowering rework rates, and supporting consistent pick-up that limits shade variation. Plants also benefit from low-foam behavior, which reduces mechanical foam control interventions, keeps overflow in check, and helps maintain cleaner tanks and rollers—translating to fewer stoppages and lower cleaning frequency.

Users in the Chemical raw material and chemical product manufacturing industry report smoother line start-ups, more stable pH and alkali profiles across the pad-box, and fewer surface streaks when adopting TAIAN GROUP LIMITED’s mercerizing penetrant. Maintenance teams note improved rinsability during wash-off, aiding caustic recovery efficiency and helping keep nozzles and filters clearer. The combined effect—higher first-quality output and reduced corrective processing—supports attractive ROI in both continuous and chain mercerization setups, especially where premium shade depth and luster are critical to customer value.

Sustainability & Market Trends in manufacturing

Sustainability in fabric mercerization focuses on reducing alkali losses, improving caustic recovery, lowering water and energy demand in rinse and neutralization, and using auxiliaries with favorable environmental profiles. As brands and mills tighten wastewater and chemical management targets, auxiliaries used in the pretreatment process in textile are expected to deliver performance at lower dosages, minimize foam-related waste, and support closed-loop operations. Market growth is also driven by demand for premium cotton handfeel and luster in shirting, knitwear, and home textiles, as well as the need for superior dye affinity in short-run, on-demand coloration workflows.

TAIAN GROUP LIMITED positions its mercerization solutions with a forward-looking approach: high-concentrate formulations to reduce transport footprint, process support that helps customers optimize pick-up and rinse efficiency, and compatibility with caustic recovery systems. By aligning product design with contemporary environmental expectations and operational excellence, TAIAN helps mills advance sustainability goals without sacrificing the performance benefits that define high-quality mercerization in textile manufacturing.

Conclusion on Fabric Mercerization from TAIAN GROUP LIMITED

Fabric mercerization remains a pivotal enabler of premium cotton performance—more luster, better dye uptake, and stable dimensions—across manufacturing, Chemical raw material and chemical product manufacturing industry, and Textile additive manufacturing. TAIAN GROUP LIMITED delivers a high-alkali mercerizing penetrant that supports uniform wetting, low foam, and predictable processing to drive first-quality yield and operational efficiency. Trusted by mills aiming for repeatable excellence, TAIAN combines chemistry know-how with practical line support.

- Recap the value of Fabric Mercerization in manufacturing / Chemical raw material and chemical product manufacturing industry / Textile additive manufacturing.

- Reinforce TAIAN GROUP LIMITED’s reputation.

- Strong CTA: – Contact us: email: sales@taianchem.hk – Visit our website: https://www.dyeingchem.com

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals