Solid Sulfur Black: an insider’s take on dye-room realities

If you’ve been around a dyehouse long enough, you’ll know that Sulphur Dyes aren’t glamorous, but they get the hard jobs done—deep blacks on cotton, utility shades on blends, rugged performance at a sensible cost. I’ve watched mills fight margin pressure and still hit fastness specs because of this chemistry. Honestly, it’s the kind of dependable tool you forget to thank.

Product snapshot

Product: Solid Sulfur Black for Textile Dyeing, made in Han Village, Zhao County, Shijiazhuang City, Hebei Province, China. It’s engineered for cotton textiles, leather and paper—and, surprisingly, it also shows up in paints, construction coatings, rubber adhesives, welding compounds, and a handful of plastic applications. Many customers say the coverage is forgiving on marginal cotton lots.

Key specifications (typical, real-world use may vary)

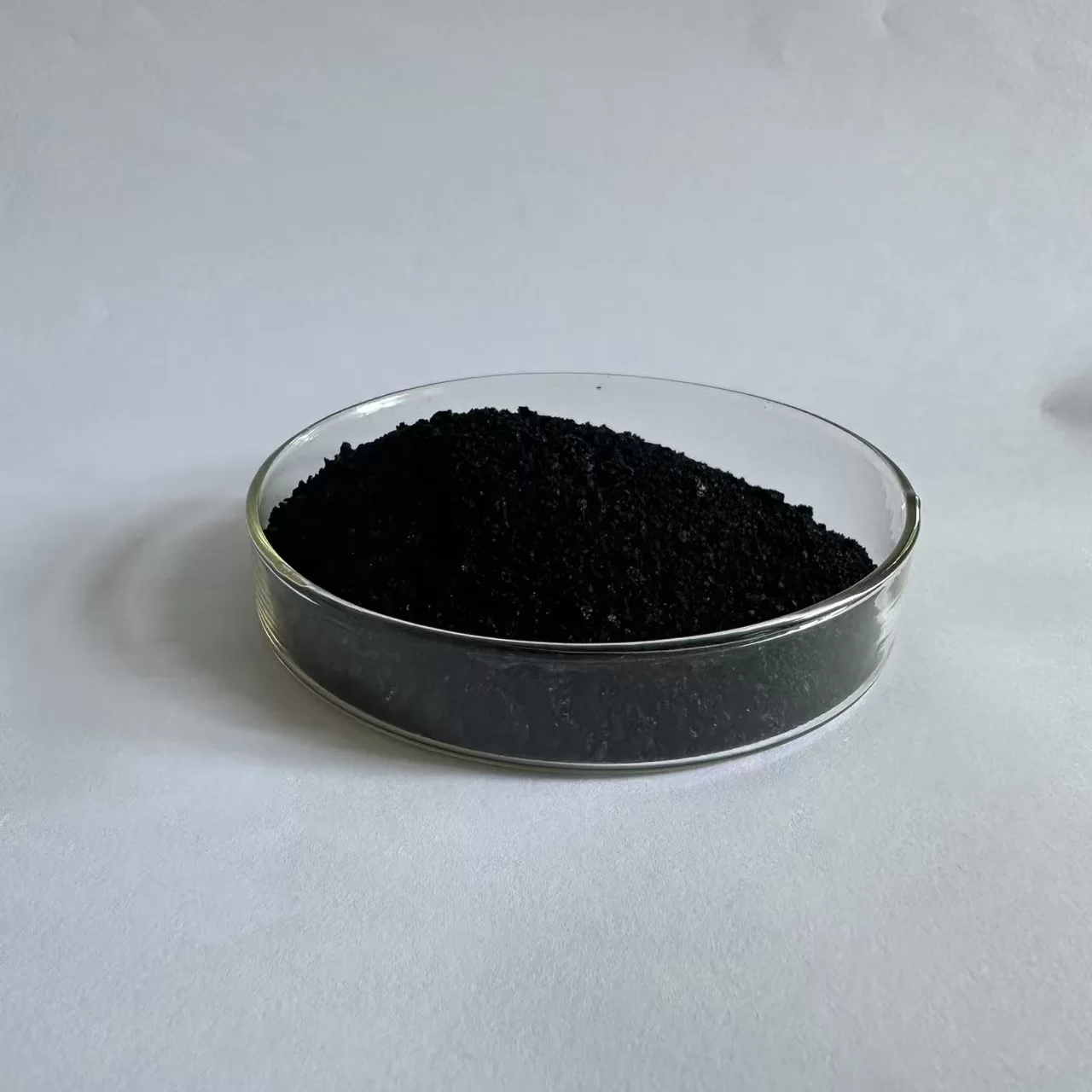

| Appearance | Granular/solid, deep black |

| Shade/Strength Index | Neutral to slightly bluish black; ≈100% ±2% lot-to-lot |

| Solubility | Insoluble in water; soluble in alkaline sulfide bath |

| Recommended Process | Jigger/WINCH or pad-steam; 80–95°C reduction; air/peroxide oxidation |

| Fastness (ISO 105) | Wash C06: 4–5; Rubbing X12: 4 dry / 3–4 wet (deep shades) |

| Shelf Life | ≈24 months in sealed, dry storage |

Process flow (how mills actually run it)

- Materials: Solid Sulfur Black; Na2S (or stabilized sulfide), soda ash, wetting agents, peroxide or air for oxidation, soaping agent.

- Method (exhaust): Wet-out → reduction at 80–90°C with Na2S + alkali → dyeing 30–60 min → rinse → oxidation (air or H2O2 ~1–2 g/L) → soap at 95°C → final rinse → neutralize.

- Method (continuous): Pad (pick-up 70–80%) → steam 102–105°C or bake 120–130°C → oxidize → wash/soap → dry.

- Testing: ISO 105-C06/AATCC 61 (wash), ISO 105-X12 (rub), ISO 105-B02 (light); for leather, ISO 11640.

- Service life on fabric: workwear/denim cycles often 50–100+ domestic washes before meaningful shade change, depending on load and finishing.

- Industries: denim, piece-dye cotton, interlinings, leather splits, kraft paper tinting, rubber & coatings.

Why mills still pick Sulphur Dyes

Cost-per-kilo of depth, robust crocking after proper oxidation/soaping, and a classic “workwear black.” Environmental note: modern recipes are moving to lower-sulfide or sulfide-free reducers. Effluent control is the name of the game, to be honest.

Vendor comparison (indicative)

| Vendor | Origin | Shade Consistency | Reducer Load | ZDHC MRSL | MOQ/Lead | Price |

|---|---|---|---|---|---|---|

| This product | Hebei, China | ±2% (good) | Moderate | Conformant (docs on request) | ≈500 kg / 10–15 days | Value |

| Vendor A | India | ±3–4% | Higher | Conformant | 1 MT / 3–4 weeks | Mid |

| Vendor B | SE Asia | ±2–3% | Lower | Conformant | 500 kg / 2–3 weeks | Mid–High |

Customization and compliance

- Tone tweaks: neutral, bluish, or slightly brownish blacks for denim vs. workwear.

- Granule sizing for fast dissolving in reduction bath—small but it matters on the jigger.

- Documentation: COA, batch test data (ISO 105), Oeko‑Tex Standard 100 statements, REACH/California Prop 65 declarations, ZDHC MRSL v3.1 alignment.

Field notes (mini case studies)

Bangladesh denim mill: Switched to this Solid Sulfur Black for base shade under Indigo. Reported rub fastness improvement from 3 to 3–4 wet after extending oxidation 5 minutes and adding 1 g/L peroxide. Throughput unchanged.

EU workwear converter: Targeted ISO 105-C06 4–5 after 60 domestic washes. Achieved with higher soda ash (3 g/L) and hotter soaping (95°C). Customer feedback: “color stay is better than last season’s lot.”

Trends to watch

Lower-sulfide or borohydride-based reduction systems, improved effluent capture, and traceability. And yes, Sulphur Dyes are moving steadily toward streamlined pad-steam with tighter analytics—shade cameras at the stenter are becoming normal, I guess.

Authoritative citations:

- ISO 105 series: Textiles—Tests for colour fastness (C06 wash, X12 rubbing, B02 light).

- AATCC 61: Colorfastness to Laundering, Accelerated.

- ZDHC MRSL v3.1 and Wastewater Guidelines—Zero Discharge of Hazardous Chemicals.

- OEKO‑TEX Standard 100—Harmful substances requirements for textiles.

- ETAD/REACH guidance on dye substances and restricted chemicals in textile processing.

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals