Solid Sulfur Black and the quiet revival of Sulphur Dyes in modern mills

Costs are up, energy is volatile, and mills want deep blacks that don’t bleed. In that context, Sulphur Dyes are having a moment again—especially on cotton and viscose. The product I’ve been watching is Solid Sulfur Black for Textile Dyeing, produced in Han Village, Zhao County, Shijiazhuang, Hebei, China. It’s admittedly old-school chemistry, but the newer low-sulfide, cleaner-oxidation recipes are surprisingly production-friendly.

Industry trends (and a few shop-floor realities)

- Shift from reactive black in certain segments to Sulphur Dyes for lower cost per deep shade and robust crock fastness after proper soaping.

- Cleaner oxidation (hydrogen peroxide, air) replacing legacy methods; ZDHC-aligned auxiliaries are now common.

- Denim piece-dyeing and garment-dye formats are using sulfur blacks for “workwear” depth at ≈20–30% lower dye cost, many customers say.

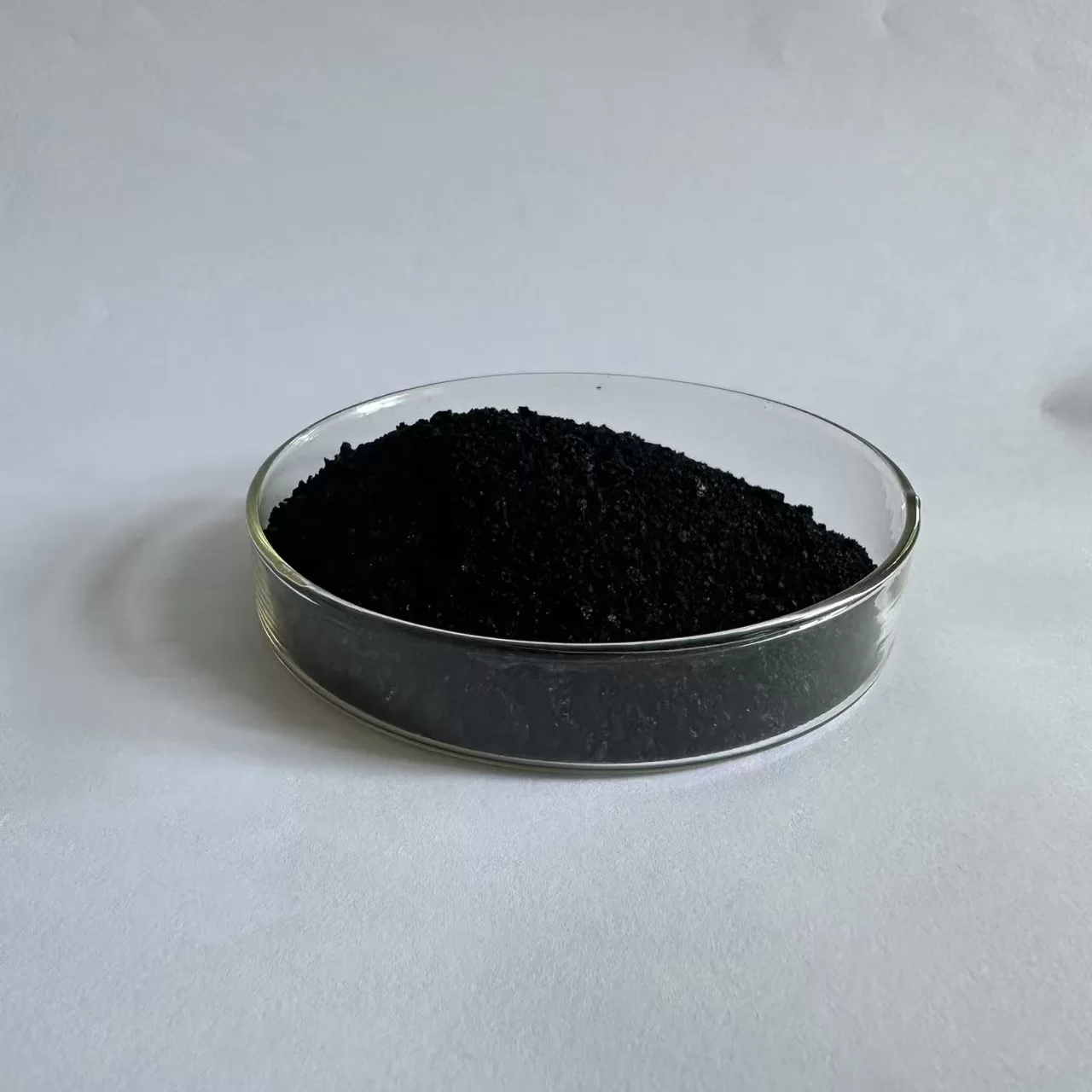

Product snapshot: Solid Sulfur Black for Textile Dyeing

A professional-grade solid sulfur black engineered for cotton, viscose, leather, and paper; it also finds its way into rubber compounding, plastics coloration, coatings/paints, rubber adhesives, and even welding compounds. To be honest, its versatility is half the charm.

| Spec | Typical Value (≈ / range) |

|---|---|

| Form / Shade | Solid granule or powder; deep bluish black |

| Solubility | Insoluble in water; soluble in sodium sulfide liquor |

| Fiber targets | Cotton, viscose, modal; paper pulp; leather crust |

| Recommended dyeing | 80–95°C, 30–60 min; pH 10–11; L:R 1:10–1:20 |

| Reductant / Alkali | Na2S (2–8 g/L) + soda ash (1–5 g/L), real-world use may vary |

| Oxidation | Air or H2O2/AcOH; rinse + soap at 95°C for best crock |

| Shelf life | ≈ 24 months, cool/dry storage |

Process flow (mill-proven)

- Prepare: Desize–scour–bleach to consistent absorbency (wetting agent optional).

- Reduction: Build stable sulfide bath; add dye; aim for clear leuco solution.

- Dyeing: 80–95°C, 30–60 min; circulate well to avoid shade bars.

- Oxidation: Air or mild H2O2; neutralize; thorough rinse.

- Soaping: 95°C with nonionic; final rinse. This is where crock jumps from 3–4 to 4–5, in my experience.

- Testing: ISO 105-C06 wash, ISO 105-X12 rub, ISO 105-E04 perspiration, ISO 105-B02 light.

Performance data (typical): wash fastness 4 at 60°C; dry rub 4–5, wet rub 3–4; perspiration 4; light 5–6. Service life on workwear: holds tone for ≈30+ industrial cycles when soaped properly.

Use cases we see most

- Denim garment dye and piece dye for deep, matte blacks.

- Yarn dyeing (ring-spun cotton) for flat, uniform shade.

- Leather crust toning; paper pulp coloration; rubber/plastic masterbatch filler black.

Vendor comparison (practical buyer view)

| Vendor | Shade consistency (ΔE) | Lead time | Compliance | Docs | Price index |

|---|---|---|---|---|---|

| DyeingChem (Hebei) | ≈ ≤0.8 | 7–12 days | ZDHC MRSL, REACH-ready | COA, SDS, technical TDS | 1.0 |

| Local Trader | ≈ 1.2–1.8 | Ex-stock | Varies | Basic COA | 0.95 |

| EU Distributor | ≈ ≤0.6 | 2–3 weeks | Full REACH, Eco Passport | COA, SDS, Ecopass | 1.25 |

Note: ΔE and pricing are indicative; real-world use may vary by batch, recipe, and logistics.

Customization and support

Shade tuning to ΔE ≤0.5, low-sulfide versions, granule size options, and private label packing (usually 25 kg). Tech teams can help migrate from reactive black to Sulphur Dyes with controlled soaping to uplift wet rub.

Field notes (quick cases)

- Bangladesh denim mill: switched to sulfur black on garment dye, dye cost down ≈12%, wet rub improved to 3–4→4 after two-step soaping.

- Turkey rubber maker: consistent jet-black gaskets using the solid form; reported better dispersion and less dusting on the mixer.

Compliance pack on request: SDS, COA, test reports vs ISO 105 series, ZDHC MRSL screening, and optional OEKO-TEX Eco Passport documentation.

Authoritative references

- ISO 105-C06: Textiles — Tests for colour fastness — Colour fastness to domestic and commercial laundering.

- ISO 105-X12: Textiles — Colour fastness to rubbing.

- ISO 105-E04: Textiles — Colour fastness to perspiration.

- ZDHC MRSL v3.x — Manufacturing Restricted Substances List.

- OEKO-TEX Eco Passport — Chemical input verification standard.

- EU REACH Regulation (EC) No 1907/2006 — Registration, Evaluation, Authorisation and Restriction of Chemicals.

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals