Fabric Mercerization is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Textile additive manufacturing. This article explores how TAIAN GROUP LIMITED supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Fabric Mercerization Overview

- Benefits & Use Cases of Fabric Mercerization in Textile additive manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Fabric Mercerization from TAIAN GROUP LIMITED

Fabric Mercerization Overview

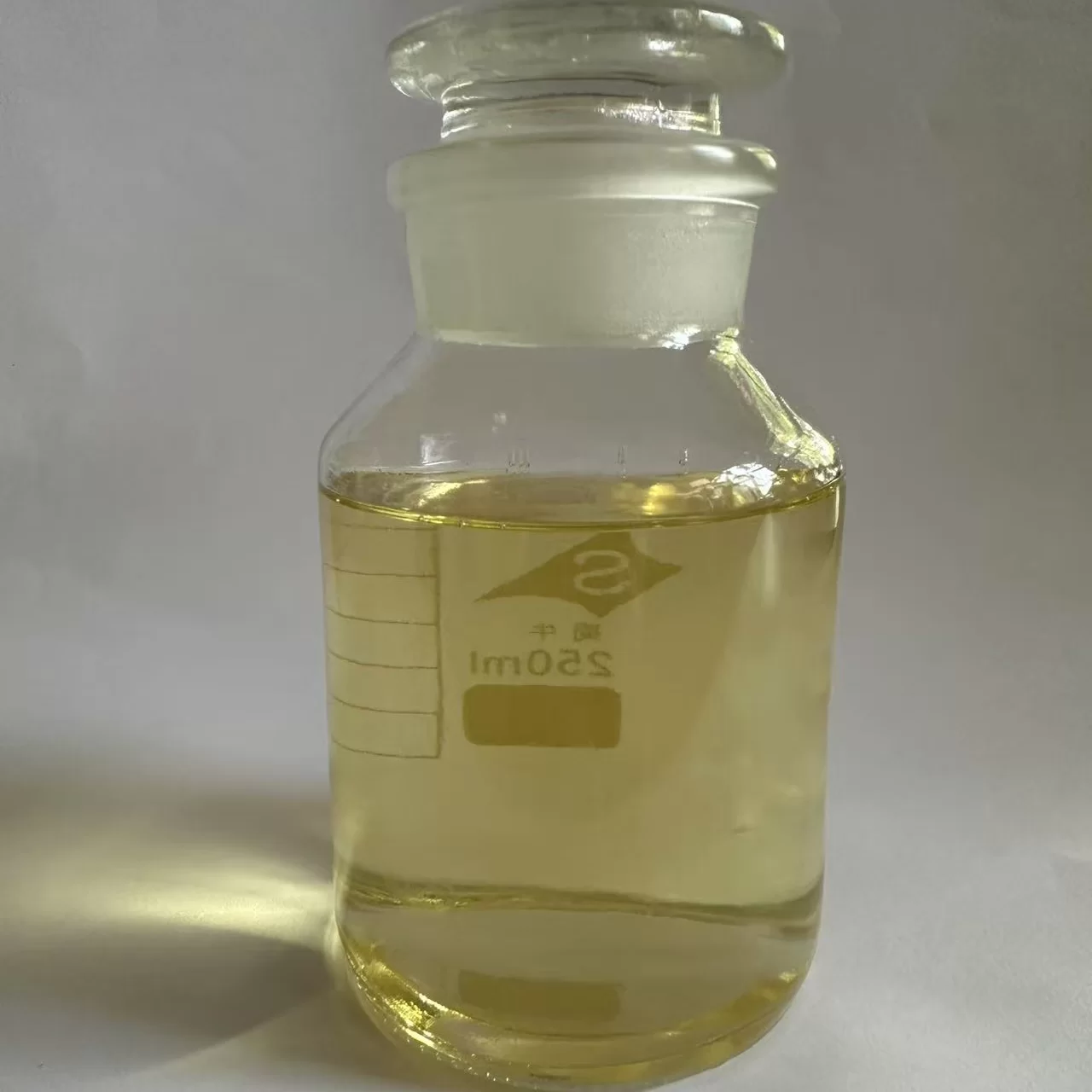

Fabric Mercerization is a controlled treatment of cellulose-rich textiles—most commonly the mercerization of cotton fabric—using concentrated alkali to swell fibers, unlock higher dye affinity, increase luster, and improve dimensional stability. In mercerization in textile processing, wetting and penetration agents are essential to ensure caustic soda rapidly and uniformly enters the fiber. TAIAN GROUP LIMITED supplies a high-alkali mercerizing penetrant engineered for the pretreatment process in textile lines, helping mills achieve consistent pick-up, clean surfaces, and reproducible results from batch to batch. For B2B decision makers, the right penetrant is the difference between a stable, high-speed line and recurring quality deviations.

- Relevance: Integral to chemical raw material workflows and textile additive manufacturing, Fabric Mercerization upgrades cotton, cotton-rich blends, and staple-based yarns for premium dyeing and finishing.

- Technical background: Advanced surfactant systems enable fast wetting in high NaOH, controlled fiber swelling, low foaming, and compatibility with continuous mercerization ranges.

- Reliable partner: TAIAN GROUP LIMITED brings formulation know-how, process guidance, and dependable supply for global mills seeking stable, scalable mercerization performance.

Benefits & Use Cases of Fabric Mercerization in Textile additive manufacturing

Across weaving, knitting, and denim facilities, mercerization in textile operations elevates both aesthetics and performance. With a high-alkali mercerizing penetrant, mills can boost line efficiency while achieving brighter shades and better handle. Typical applications include woven shirtings needing high luster, knitted fabrics requiring improved dimensional stability, denim yarn mercerization for deep, even indigo shade build, and cotton-home textiles targeting superior dye uptake. When used as part of a robust pretreatment process in textile production, the penetrant supports uniform alkali penetration, minimized streaks, and reliable shade reproducibility at scale.

- Key features: High-alkali stability, rapid wetting, low foam profile, and compatibility with caustic recovery systems help ensure consistent fabric or yarn mercerization.

- Competitive advantages: Enhanced dye affinity, improved luster and smoothness, fewer defects, and the potential for higher running speeds without sacrificing quality.

- TAIAN GROUP LIMITED expertise: From formulation selection to line optimization, TAIAN provides technical support that aligns chemical choice with machine setup, fabric construction, and end-use targets.

Cost, Maintenance & User Experience

Total cost of ownership in Fabric Mercerization hinges on consistent results, reduced rework, and smooth line throughput. A penetrant designed for strong-alkali environments supports stable pick-up, reduced foaming incidents, and efficient washing-off—factors that can lower operational costs. When line stops are minimized and mercerization quality improves, mills often see stronger first-pass yield and better dye utilization, contributing to measurable ROI over time.

- Durability & ROI: Robust, high-alkali-stable chemistry sustains performance across long runs, helping protect margins by reducing defects and downtime.

- User experience: Process teams report easier bath control, predictable wetting, and smoother transition to dyeing. Best practices include inline monitoring of NaOH concentration, pick-up targets, and foam, plus calibrated dosing for the penetrant.

Sustainability & Market Trends in manufacturing

Sustainability expectations in the textile supply chain continue to rise, with brands and regulators prioritizing resource efficiency, safer chemistries, and wastewater performance. In this context, Fabric Mercerization benefits from penetrants that support efficient alkali penetration, controlled foaming, and compatibility with caustic recovery systems—helping mills improve yield and reduce waste. The trajectory of market demand for premium cotton goods, combined with stricter environmental standards, makes the choice of auxiliaries critical for long-term compliance and competitiveness.

- Sustainability focus: Optimized processes can reduce water and energy usage through fewer reworks and stable line speeds, while modern formulations aim to minimize unnecessary additives.

- TAIAN GROUP LIMITED approach: With a forward-looking R&D mindset, TAIAN emphasizes performance, process efficiency, and responsible chemistry selection to help mills meet evolving environmental and market expectations.

Conclusion on Fabric Mercerization from TAIAN GROUP LIMITED

Fabric Mercerization remains a cornerstone of quality enhancement in manufacturing, especially across Chemical raw material and chemical product manufacturing industry and Textile additive manufacturing. By integrating a purpose-built penetrant into the pretreatment process in textile production, mills can unlock superior dye affinity, luster, and stability—while safeguarding productivity. As a dependable supplier, TAIAN GROUP LIMITED delivers performance-driven solutions and technical guidance that align with your operational goals. Contact us: email: sales@taianchem.hk. Visit our website: https://www.dyeingchem.com

Our team comprises seasoned manufacturing experts and international business professionals.dye auxiliaries Core team members possess 15-20 years of industry experience,textile auxiliary manufacturer with deep understanding of every production detail and sharp market insights.textile auxiliary agent Our professional teams include:R&D Team: Continuous innovation, leading industry development Production Management Team: Pursuing excellence,auxiliaries chemicals ensuring stable quality Quality Control Team: Strict supervision with zero-tolerance attitude International Business Team: Professional service with seamless communication.textile auxiliaries chemicals